In contrast a packed column provides a continuous surface throughout the volume of the column. A the surface area.

Pdf Enhanced Methanol Recovery And Glycerol Separation In Biodiesel Production Dwc Makes It Happen

Abayomi BCH2008001 as the group leader Obafemi Awolowo University SUBMITTED TO.

. A 5 percent increase of methanol composition Tray Temperature Control As pointed out temperature and pressure are among significant variables of a distillation column. Methanol water distillation chemical. Instead it is lled with a packing that gives a high surface area for apvor and liquid to react thus increasing e ciency.

It is then split equally and fed to two distillation columns one at 72 bar and the other one at reduced pressure 52 bar. It therefore requires a lot of heat energy heavy boiling to achieve the required. Water is a byproduct.

A fixed amount of synthesis gas is fed into the system and. Relative volatility that are used for distillation process design are given in Table 52. Early attempts to produce refined methyl acetate via re- active distillation failed because the formation of azeo- tropes was not recognized 3.

There are many types of distillation columns each of which is designed to 1. ET is the ex-tractive distillation column which operates at 50kPa and MT is the methanol distillation column operating at normal pressure. Distillation column is above atmospheric pressure.

The pure methanol is separated on the top of this. Definition of inputs and outputs in SimulinkMatlab Fig. The flowsheet is shown in.

Choose an operating pressure 3. FDistillation Column Design 2012. Afterwards the output of the bottom.

The factors that affect distillation column operation Lets clarify some of the termonology that is used in distillation by considering a two component mixture eg. A very tall distillation column is required for separating water from methanol. Assume operating reflux ratio is 125 of minimum reflux ratio.

The bottom mixture gets a further separation in another column at normal pressure. Methanol 257-364 234801 362655 -3429. This features allows the column to operate for a long time with a relative small amount of feed.

In this operation the distillate and bottom products are recombined and directed to the. The distillation process was simulated by Aspen Plus v72 with NRTL as the property method 14. The output water in the third column reduced from 0999 to 0889.

EIGHT PRACTICAL STEPS 1. Full PDF Package Download Full PDF Package. 3001enters the 70 th stage of the column T -3002 and.

The water which boils at a higher temperature is separated from product methanol. The gas-phase exothermic reactions are conducted in a packed tubular reactor which is cooled by generating steam. Overview of distillation column function 5 A trayed distillation column has multiple trays that provide surfaces for achieving equilibrium.

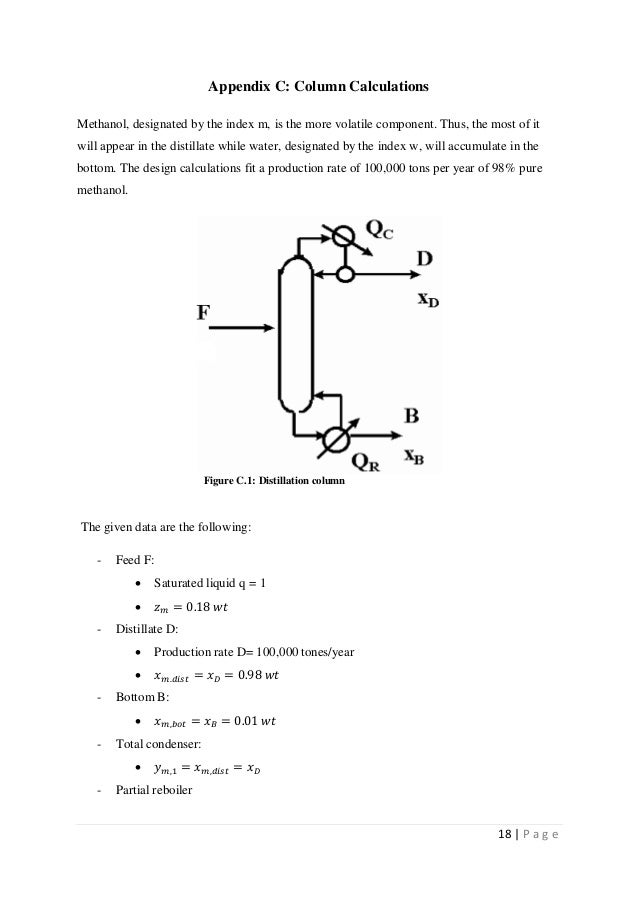

Therefore the aim of this report is to design a distillation column for the separation of methanol water mixture. 35 Calculation of Operating Reflux Ratio. The paper as such best describes the modeling and simulation of a distillation column using ASPEN PLUS to obtain 995 composition of methanol in.

Distillation Column Design 2012 Prasanna Welahetti Page 11 35 Calculation of Operating Reflux Ratio No hard and fast rules can be given for the selection of the design reflux ratio but for many systems the optimum will lie between 12 to 15 times the minimum reflux ratios. A distillation column separates methanol from water. DISTILLATION COLUMN DESIGN AND ANALYSIS 8TH AICHE SOUTHWEST PROCESS TECHNOLOGY CONFERENCE OCTOBER 6-7 2016 I GALVESTON TX.

1 11 Packed Column A packed distillation does not contrary to ie. Theory for this experiment is mainly found from DistInstructpdf. A sieve-tray column or an Oldershow column have a set number of trays.

Due to the complexity of distillation process. Usually shorter than trayed columns. Gas to produce methanol.

Journal of the department of chemical engineering Obafemi Awolowo University 2013Volume1 001-006 BATCH DISTILLATION OF METHANOL FROM ITS AQUEOUS SOLUTION WATER GROUP ONE MEMBER K. It also shows the optimal location to feed the binary mixture in the column. Distillation columns and a column with an extractive agent such as ethylene glycol monomethyl ether 2 to act as an entrainer to separate the methyl acetate from methanol.

MR SANDA Department of Chemical Engineering Date submitted. Pure water has a boiling point of 100 0C and pure methanol has a boiling point of 65 C. Of the column T.

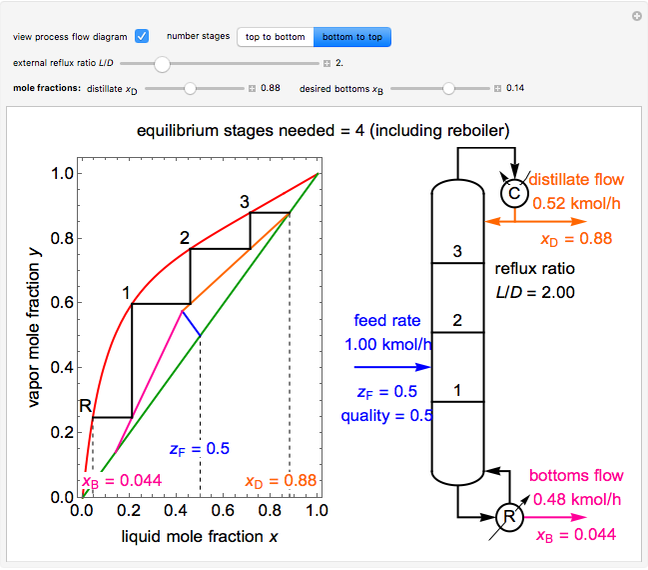

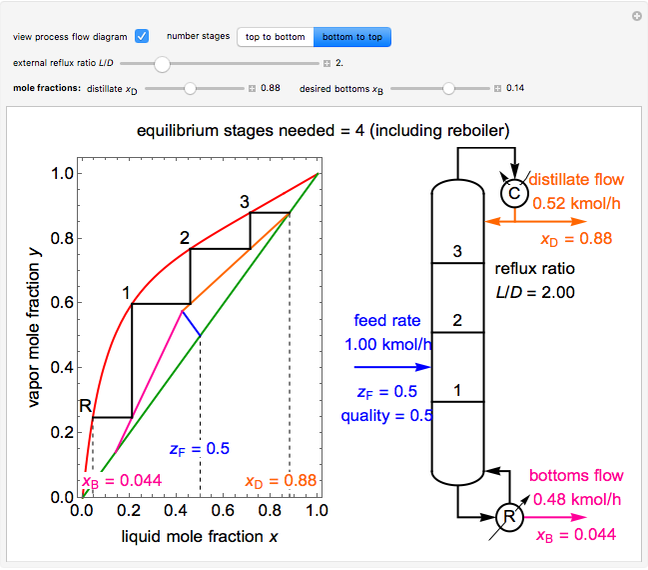

Define product specifications 2. This simulation shows how to determine the number of equilibrium stages required for a separation of two components methanolwater in a counter-current distillation column. Distillation column design and 5.

21 Distillation Column Apparatus The TECHNOVATE Fractional Distillation Column can be operated in a constant recycle mode. Dehydration is achieved commonly by distillation to provide for commercial methanol that is nearly free of water Feed conditions of the process are 2700 kgmolehr at 25oC and 72 bar. Distillation is the most well known separation technique used in the industry sector.

More recent work 4 found. No hard and fast rules can be given for the selection of the design reflux ratio but for many systems the optimum will lie between 12 to 15 times the minimum reflux ratios. Choose appropriate VLE data 4.

Water and methanol having different boiling points can be separated through distillation. If the column pressure required to accomplish overhead condensation with cooling water is less than 250 lbin2 then the column pressure should give an average temperature driving force of 5-15C in the overhead condenser. Distillation Column Design Methanol-Water separation Distillation Column Design 2012.

Luyben 2009-03-30 After an overview of the fundamentals limitations and scope of reactive distillation this book uses rigorous models for steady-state design and dynamic analysis of different types of reactive distillation columns and quantitatively compares the. DISTILLATIONABSORPTION COLUMN DESIGN ChE 4253 - Design I Complex Columns Heat Integrated Distillation Columns HIDiC. A short summary of this paper.

A large gas recycle stream is required to obtain high overall conversion. This is because these two materials like each other a lot and are reluctant to separate. Assume operating reflux ratio is 125 of minimum reflux ratio.

Column shell should be thicker to withstand pressure of the column. The efficacy of packing can be distilled down to two values. Some optimal relative volatility that are used for distillation process design.

NPTEL Chemical Mass Transfer. Methanol water distillation column design pdf Methanol-water distillation column design pdf. Download View Distillation Column Design methanol-water as PDF for free.

34 Full PDFs related to. A simple binary system of 50 water and 50 methanol. Reactive Distillation Design and Control William L.

Mccabe Thiele Method For Methanol Water Separation Wolfram Demonstrations Project

Pdf Design And Co Simulate Control Of An Extractive Distillation Column Using Aspen Plus Dynamics With Matlab And Simulink Toolbox Semantic Scholar

The Methanol Water Distillation Column Download Scientific Diagram

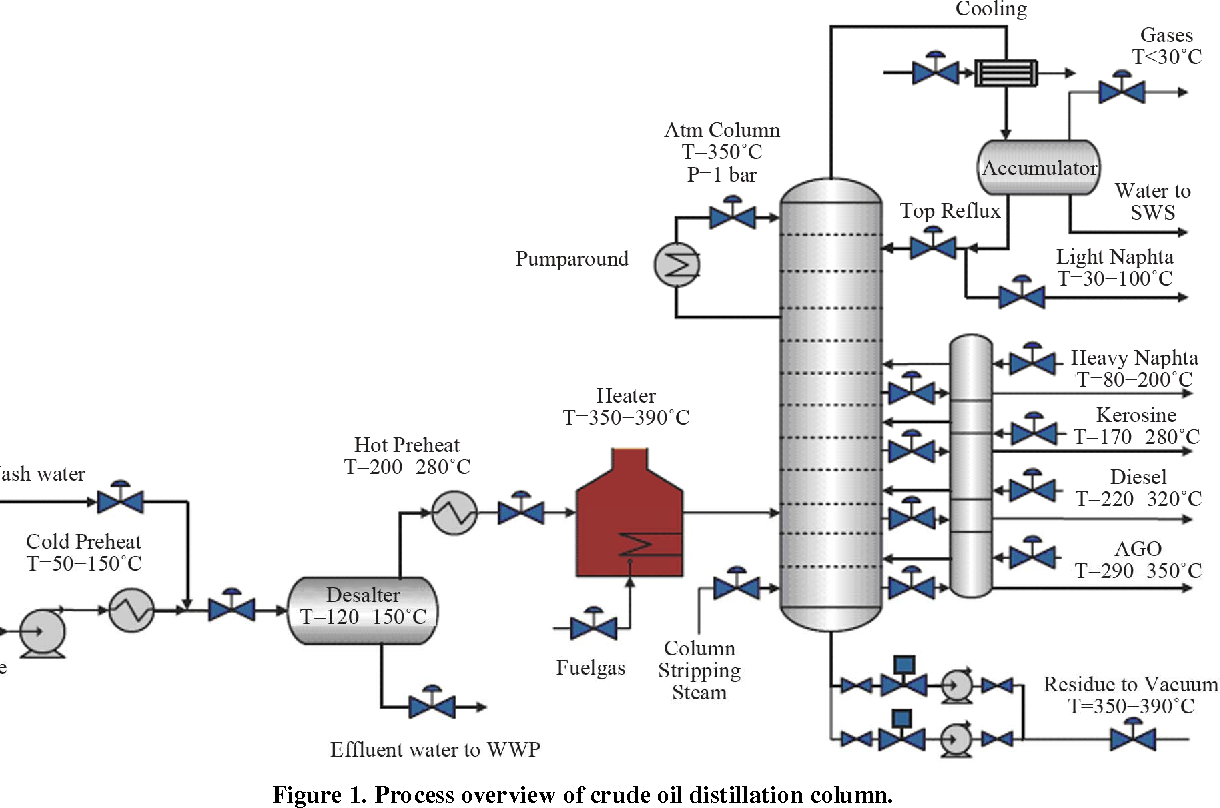

Pdf A Review Of An Expert System Design For Crude Oil Distillation Column Using The Neural Networks Model And Process Optimization And Control Using Genetic Algorithm Framework Semantic Scholar

Pdf Design And Control Of Extractive Distillation For The Separation Of Methyl Acetate Methanol Water

Design Of Methanol Water Distillation Column

The Methanol Water Distillation Column Download Scientific Diagram

0 comments

Post a Comment